Head Implant¶

Required Tools¶

Ruler

Soldering iron

Tweezers

Bill of Materials¶

Qty |

Description |

Datasheet |

Order Link |

|---|---|---|---|

1 |

Implant PCB |

||

1 |

Laser Diode |

||

1 |

Fiber |

F-MBB |

|

1 |

UV curing adhesive |

||

1 |

Ferrule |

||

1 |

Epoxy |

||

2 |

Micro USB vertical socket |

||

2 |

Heat shrink tubing |

||

2 |

0603 10 kΩ Resistor |

||

1 |

0603 20 kΩ Resistor |

Assembly Instructions¶

Prepare Fiber¶

Tape down the fiber

Use a fiber stripper to remove the outer blue jacket from the fiber

Using a fiber cleaver, cut off the end of fiber to make a clean tip

Continue cutting the fiber into ~16mm pieces

Align Fiber¶

Insert laser diode into connector

Place connector in alignment jig

Place fiber in alignment jig

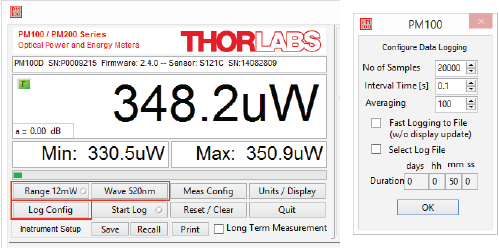

Turn on the power meter and connect to computer over usb

Open up the Thorlabs’ Power Meter Software

Establish the USB connection with Power meter by selecting the device and clicking “OK”

Adjust the following settings:

Range: 12mW

Wave: 520nm

Log Configuration

No of Samples: 20,000

Interval Time: 0.1

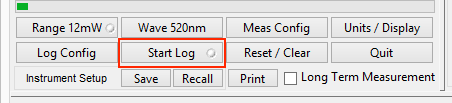

Click

Start Log

Set the power supply to 8.0 volts with a current limit of 300 mA

Provide power to the laser diode by pressing the “on/off” button

While watching the power graph update, use the 3-axis fiber launch system to adjust the x, y, and z alignment of the fiber with respect to the laser diode.

When you are happy with the alignment, apply UV curing adhesive to the fiber/laserdiode junction.

Cure the adhesive using UV light

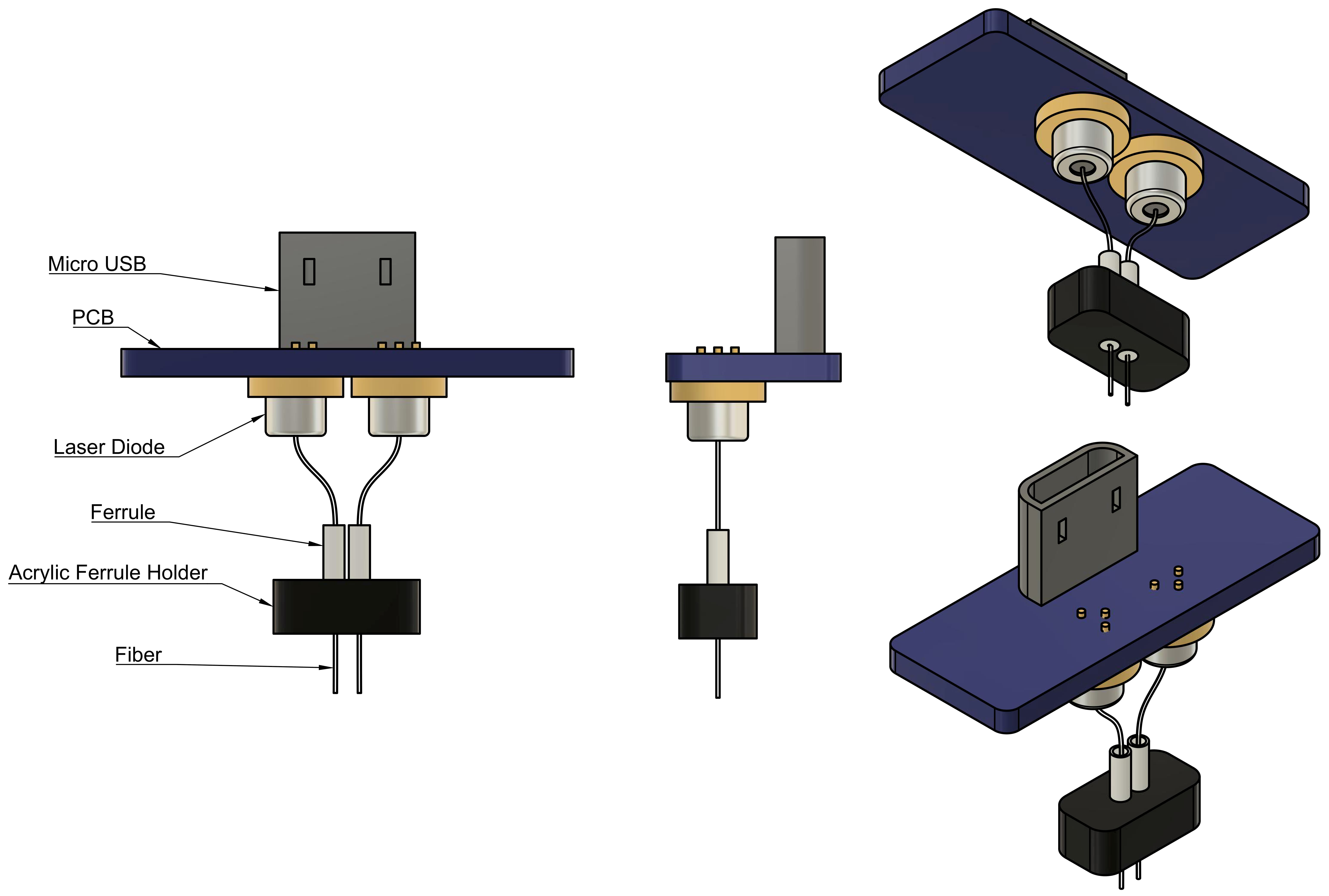

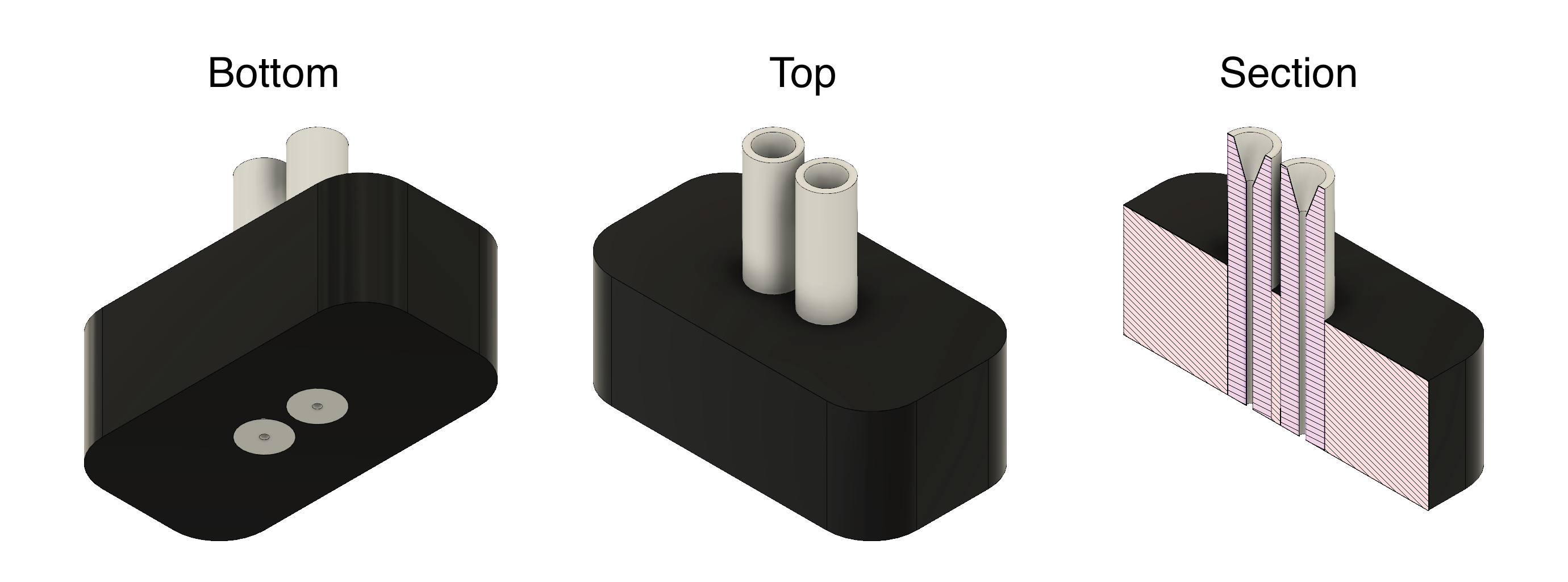

Fiber Guide Construction¶

A fiber guide is needed to ensure that the fibers are at a precise distance apart, and are parallel. The distance will depend on what area of the brain is being targeted. Below are files for 1.5 mm and 2.74 mm gap between fibers.

The laser cutter speed and power settings may need to be tweaked to get a good fit for the the ceramic ferrules.

Insert the ceramic ferrules into the acrylic fiber guide. The flat side of the ferrules should be flush with the face of the acrylic.

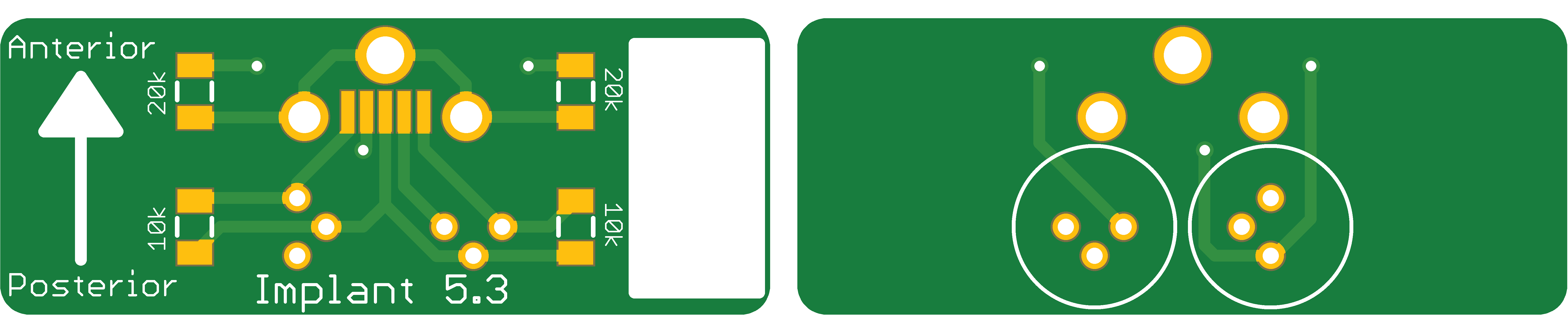

Combine PCB, Laser Diodes, and Fiber Guide¶

Solder the vertical microusb connector onto the PCB

Solder 1 leg of each laser diode onto the PCB

Bend the laser diodes toward eachother so the tips of the fiber slightly intersect near their tips

Solder the remaining legs of the laser diodes

Cut ~10mm of heat shrink tubing and slide it onto one of the laser diodes

Apply heat to the heat shrink tubing

Warning

Heat can weaken the UV glue that is used to attach the fiber. Be careful not to apply too much heat for too long as you may risk weakening the glue, causing the fiber to move out of alignment or detach completely.

Slide the fiber guide onto the two fibers. Adjust the

Surround the fibers and laser diodes with epoxy

Place heatshrink tubing around the clear epoxy section of the implant

Place and solder the remaining resistors onto the PCB